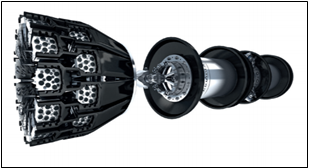

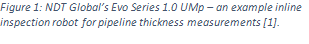

This project is investigating the use of advanced excitation techniques to improve the performance of inline inspection robots. Inline robots are used to monitor the structural health and integrity of large pipeline structures. This project aims to understand how advanced excitation techniques may help to improve the sensitivity, energy consumption, size, and design of ultrasound acquisition systems on inline robots.

Currently, traditional excitation methods with high voltage pulses are used to yield sufficient Signal-to-Noise Ratios (SNRs) in the acquired signals. However, high voltage pulsers are inefficient [2] which increases the required energy that must be stored and carried by the robot. Additionally, typical robots incorporate large numbers of ultrasound transducers to ensure the full pipe structure is inspected which introduces problems with crosstalk. Crosstalk from both electronic and ultrasonic pickup between adjacent measurements complicates signal analysis and imposes spacing constraints between transducers. Signal variation introduced by differences across transducers also complicates the signal analysis. These challenges result in strict design requirements and an increased robot build and operating cost.

Coded Excitation has the potential to overcome these challenges. Literature has shown that Coded Excitation allows measurements with low excitation voltages [3]; can be used to optimise and standardise waveforms from transducers [4]; and can reduce crosstalk and increase imaging rate [5]. Therefore, Coded Excitation has the potential to improve inline robot performance and design.

This project initially focussed on the fundamentals of Coded Excitation. This involved exploring how Coded Excitation impacts SNR and how the code can be optimised for different measurements. The project now looks to investigate: the robustness of Coded Excitation on different hardware; alternative sequence types and their performance limits; sequence orthogonality and crosstalk; optimising transducer standardisation; and hardware requirements for low-power modular implementations.

References:

[1] – NDT Global Ltd. ‘UT corrosion inspection technology – web article’. https://www.ndt-global.com/resources/download/ultrasonic-metal-loss-inspection-flyer/, Accessed – 13/10/2021.

[2] – J. Choi, S. Youn, J.Y. Hwang, S. Ha, C. Kim, M. Je. ‘Energy-efficient high-voltage pulsers for ultrasound transducers’. IEEE Transactions on Circuits and Systems, 68-1, 19:23, 2021.

[3] – J. Isla and F. Cegla, ‘Coded excitation for low SNR pulse-echo systems: Enabling quasi-real-time low-power EMATs’. 2016 IEEE International Ultrasonics Symposium (IUS), 2016

[4] – P. Kaczkowski. ‘Arbitrary waveform generation with the Verasonics research ultrasound platform’. 2016.

[5] – Y. Tasinkevych, I. Trots, A. Nowicki. ‘Mutually orthogonal Golay complementary sequences in the simultaneous synthetic aperture method for medical ultrasound diagnostics. An experimental study’. Ultrasonics, Volume 115, 2021.